Organic Tree Fruit Production

It is possible to grow tree fruits organically that are equal in quantity and quality to conventional produce. The following are areas that may require management changes by conventional tree fruit growers in order for them to become certified as organic producers.

Soil Management and Fertilization

Soil building and maintenance is a basic tenet of organic production. To satisfy this requirement most organic tree fruit growers use compost. Materials like blood and feather meals or fish fertilizers are a source of nitrogen, but are only supplements to and not a replacement for a proper soil building program. Compost supplies the soil with nitrogen directly and also with organic matter to serve as a slow release source of nitrogen. It also supplies other important nutrients, conserves soil moisture, and provides a favourable medium for soil organisms to flourish.

Compost made on the farm must reach a temperature of 55°C for four consecutive days or meet CCME (Canadian Council of Ministers of the Environment) acceptable levels for human pathogens; otherwise operators must adhere to the raw manure application requirements laid out in the standards. Compost from off-farm can be used as well, but there are three restrictions for off-farm compost sources; 1) must be CCME Category A grade compost, 2) can’t lead to a heavy metal buildup and, 3) must meet CCME’s human pathogen levels; see the “Compost obtained from on-farm sources” listing in Section 4.2 of CAN/CGSB 32.311 for details.

Rates of application are determined by analysis of the compost for: nutrient and minerals, salts and pH; as well as the vigour, age, variety, tree fruit commodity and cropping history of the orchard. Raw manures can be applied under very restricted circumstances; in the case of tree fruits it must be applied at least 90 days before harvest. Manures from non-organic operations where livestock is fully caged and not able to turn 360° (e.g. veal or farrowing crates) or where animals are kept permanently in the dark are not allowed.

Common materials used to make finished compost are livestock or chicken manures mixed with sawdust or woodchips, with the compost often taking approximately six months to make. Acceptable compost feedstock include animal manure with restrictions as noted above; fish by-products and plant residue from any source; soils and minerals that conform to CAN/CGSB 32.310 and 32.311. Use of these products requires documentation to confirm they are not contaminated with materials prohibited by the Standard, and if purchased that the material was composted effectively meeting the Standard. Prohibited feedstock include sewage sludge, substances not included in the standard or prohibited by 1.4.1 of CAN/CGSB 32.310; leather by-products; glossy paper; waxed cardboard; paper containing coloured ink; animal products and animal by-products that are not guaranteed free of specified risk materials (refer to the “Bone Meal” listing in CAN/CGSB 32.311 section 4.2).

Growers exporting to Europe will need to confirm with their Certifier if additional documentation is needed to verify manures from non-organic farms came from animals that were not fed Genetically Engineered Organisms.

Micronutrients such as boron, magnesium and zinc can be used if a soil and/or leaf tissue analysis shows a deficiency. Mined minerals and unprocessed mined mineral are allowed sources of nutrients. Calcium chloride, only derived from limestone, can be used to address nutrient deficiencies and/or physiological disorders.

Pest Management

Common organic production methods include orchard sanitation, monitoring pest and predator populations, and the deployment of selected pesticide and other passive control measures. The overall objective is to encourage the development of a healthy predator/pest balance, which will minimize the need for human intervention. Under organic regimes, campylomma, pest mites, pear psylla and tentiform leafminer decline dramatically and cease to be a problem. Codling moth control, once the most difficult pest to control in organic pome fruit production in the south Okanagan and Similkameen valleys is much less of a problem due in part to the SIR program and mating disruption. Organic apple and pear production occurs mainly in the Similkameen Valley where low wild populations of codling moth are present. Codling moth populations can be maintained below economic thresholds by the release of sterile moths, or by combinations of sterile moth release and pheromone mating disruption. Apply the organic-approved biological product Virosoft CP-4 (contains a live virus specific for codling moth) when and where codling moth levels exceed acceptable levels. Entrust (spinosad) is approved for application to suppress codling moth populations.

One or two spring applications of Dipel 2X DF (Bacillus thuringiensis) plus native predators and parasites, are effective in controlling leafrollers and fruitworms. There may be a need for one or two additional Bt sprays to control summer populations of obliquebanded leafroller (OBLR) and eyespotted bud moth in areas where they occur. Entrust (spinosad) is also approved for control of leafrollers, eyespotted bud moth and apple clear-wing moth in pome fruits. Isomate-CM/LR is approved for control of codling moth and leafrollers in pome and soft fruits.

Control of apple scab and powdery mildew has been reported with spray applications of lime sulphur beginning at 20-40% full bloom and again at full bloom. Sprays of lime sulphur at petal fall may increase the risk of fruit russet, especially when weather conditions are cool and damp. Several sprays of wettable sulphur may be needed to control powdery mildew on susceptible varieties. Wettable sulphur also provides protection against apple scab. While scab is easily controlled in the dry interior climate, as many as 10 to 12 sprays may be needed in wet areas such as the Fraser Valley. In these areas anthracnose is also a major problem. Sanitation practices such as removal or flail mowing of fallen leaves and pruning out mildew-infected white tips are also effective in reducing disease pressures.

Soft fruits can be more of a challenge. Entrust 80W is also registered for control of leafrollers and eyespotted bud moth in stone fruits (maximum 3 applications/season), and for control of cherry fruit flies in cherries (maximum 4 applications/season). GF-120, a bait formulation of spinosad, is OMRI-approved and registered for control of cherry fruit flies and apple maggot (maximum 10 applications per year). All unharvested fruit must be destroyed after harvest to remove breeding sites. Summerland PARC scientists are presently validating models to predict the first adult emergence and first adult detection in various Valley microclimates. Degree Day models that have proven useful in Oregon, Utah and Washington can be reviewed at: http://www.ipm.ucdavis.edu/PHENOLOGY/ma-w_cherry_fruit_fly.html

There are no organic approved fungicides that are effective against brown rot. In the Similkameen Valley, because of the climate, brown rot is not a constraint, but in wetter climates, it can result in major crop losses in all soft fruits. Sanitation, open tree training, and loose fruit clusters will help minimize outbreaks.

Peach tree borer mating disruption has replaced annual tree trunk wrapping procedures completely. Thrips control in nectarines is difficult and seems to be worse if the dandelions don’t bloom at the same time or the dandelions are mowed off. Earwigs are easily and well controlled by installation of barriers in the spring. Appropriately timed applications of Bacillus thuringiensis can deliver effective control of twig borer.

Controlling voles, Columbian ground squirrel and pocket gophers requires vigilance. To keep damage from voles low means keeping it clean around the trees with cultivation and/or weed eaters. Encouraging predators, and trapping using Tin Cats, are also options. Pocket gophers can be controlled by use of Black Hole traps. Control the Columbian ground squirrel by trapping.

Keeping land fallow for a year and/or growing crops antagonistic to diseases and nematodes generally deals with potential replant problems.

Organic growers must practice due diligence when selecting inputs and should verify product acceptability with their Certification Body (CB) before use. Some certifying bodies have published approved lists. There is an industry driven initiative attempting to collate a national list of approved pest/disease/plant control and plant nutrient products. Interested growers should contact the Certified Organic Associations of BC (COABC) in Vernon for a list of certifying bodies and their contact information.

Growth Regulators

Natural plant hormones (such as gibberllic acid, indoleactic acid and cytokinins) are allowed in the Canada Organic Standard; so are non-synthetic amino acids produced by plants, animals and microorganisms that are not the products of biotechnology. Check with your certifier for brand name products.

Thinning

Until recently, thinning could be the largest single expense in an organic apple orchard because it was all done by hand. While hand thinning is still an important tool to finesse crop load, many growers have had success with managing crop load by judicious pruning and bud counting. For example a super spindle planting 1.5’x 9’ (3300 trees/acre) requires only 25 fruit buds/apples per tree for a 50 bin/acre crop of size 100 apples. Intensive pruning maintains an open tree for optimum light, and air penetration stimulates flower bud formation and sustains spur vigour.

Low dose lime sulphur mixed with fish oil applied at 20% full bloom through petal fall as the side blooms open has shown to be an effective spray thinner suppressing photosynthesis for up to 6 weeks by as much as 20% per application. Scientists speculate that combined effects of caustic burning of flowers and stress to the trees are causing fruit to thin. Growers are advised to use caution when attempting to use this treatment for apple thinning. Neither lime sulphur nor any fish oil products are registered by PMRA for apple thinning.

Vegetation Management

There are no herbicides allowed in organic production registered in Canada. In tree fruits, cultivation around the trees - usually by a Rinieri cultivator or a Weed Badger, 2-4 times a year - is common practice. Weed eaters are also used. This is done to remove competition from vegetation for the trees and for vole control. Other techniques such as flaming and mulching are sometimes used but both have limitations and more commonly used on rocky sites.

It is both possible and desirable to develop a tolerance for weed growth. There are times of the year when growth around the trees does no harm and can even be helpful in temporarily removing excess nitrogen, which might negatively affect fruit quality.

Planting Stock

Non-organic nursery stock from the date of planting must go through a year transition period before the crop may be sold as organic. Growers must provide proof of attempting to obtain organic planting stock before using non-organic planting stock. Most certifiers require this evidence to be in the form of email correspondence or records of phone calls.

Trellises

If you already have CCA treated posts, you will not have to remove them. However, after you enter a certification program, further purchases and installations are prohibited. Organic growers are using metal and cedar posts. Other types of untreated wood and concrete would also be allowed.

Marketing and Handling

Organic fruit is sold into different markets by different methods. Some growers sell through farmers markets, box programs or at the farm gate. Others use one or more brokers. Organic growers are as a rule much more involved with the marketing of their fruit than a typical traditional grower would be. While this does take more time, you are also much more in touch with market conditions.

For storage and packing, you can either arrange with a conventional packinghouse to become certified to meet organic requirements or deal with an organic house.

Organic production stresses personal accountability. Depending on the type of marketing your name, contact information and the name of your certifier must be on every box; or in the organic packing house situation every box must at least carry a tracking code.

Certification and Accountability

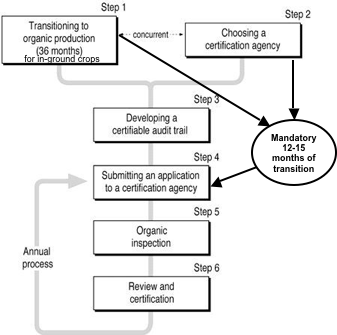

Certification is a process of inspection and verification that is required for consumer confidence. If you do want to make an organic claim, you must join a certification organization and receive full organic certification status if your product is going to be marketed outside the province. There are roughly 6 steps in the certification process.

Step 1 - Transition to organic production

1) Transition is the period of time between the start of organic management and the time a farm is brought into accordance with organic standards.

2) Thirty-six months of transition is required from the last application of a prohibited substance.

3) A soil management plan must be implemented during that time.

4) The last 12 months of transition must be completed within a certification program. At minimum new applications must be submitted 15 months before a crop can be marketed as organic.

5) Enterprises must aim for a complete transition of its production. The enterprise can be converted to organic production one unit at a time. Parallel production (where the products of the organic and non-organic system are indistinguishable) is not allowed.

Step 2 – Choosing a certification agency

The Certified Organic Associations of BC is designated as the provincial organic program administrator and serves as the accreditation body for eleven member-certifying associations.

1) Great diversity can exist among certification agencies and you must choose a program that best meets your needs. Considerations must include:

a) Market destination because if you plan to ship out of the province or export, you must be certified by an agency that is ISO/IEC 17065 compliant. The COABC website has a list of Certification Bodies that have either: been accredited by the Canadian Food Inspection Agency (CFIA) to certify organic products; or recognized under an organic trade equivalency arrangement.

b) Reputation

c) Costs

2) Talking with other organic growers may help you choose an appropriate certification agency.

Step 3 - Developing a certifiable audit trail

1) Review all certification procedures to determine if you meet organic standards and regulatory requirements.

2) Implement record keeping (detailed production, sales and input records) for all pertinent aspects of your operation.

3) Create an accurate visual record (layouts, maps, flow diagrams).

4) List all production units, yields, varieties or if processing, current products.

5) Fill out application, also known as the Organic Farm Plan; attach map, diagram(s), sample record keeping, soil or irrigation water test if required by the Certifier, and where applicable labels. Submit completed affidavit. As well, submit a current water potability test especially if water is used during processing as an ingredient, processing aid or cleaning agent. Keep a copy of your complete application.

Step 4 - Submitting an application to a certification agency

1) The Certification Committee representative will complete a preliminary review of your application.

2) A 3rd party inspector will be assigned your file and an inspection scheduled.

3) The actual inspection may involve 1-5 hours depending on the complexity of the operation.

Step 5 - Organic inspection

1) The inspector will verify all forms, maps and information supplied.

2) A visual inspection of the total operation, including your record keeping system, will take place.

3) An assessment of potential contamination points/risks will be made.

4) The inspector will submit a report to the Certification Committee.

5) The inspector does not determine status.

Step 6 - Review and certification

The Certification Committee will assess the file and could:

1) Approve your request for membership.

2) Assign a status (transitional or certified organic) or,

3) Approve your request pending implementation of conditions or,

4) Deny your request based on their Standards.

The certification process is repeated annually. And even if you break the rules accidentally, you may be required to sell the affected product conventionally. At the most, you might be decertified.

No Quick Fixes but Sometimes Some Long Term Ones

There are very few if any quick fixes in organic production. For example, mulching around tree trunks may seem like a great idea to manage annuals weeds but what are you going to do if you start having a rodent problem? Also once the mulch is installed, bindweed, quack grass and Canada thistle might outgrow your trees. You have to make a greater effort to be aware of the repercussions of every action taken.

In addition, organic growers have to adjust crop levels to correspond with the capacity of the site or problems will definitely arise. With the aid of a good soil-building program you can produce high quality organic fruit on an on-going basis. As well, over time as you learn how to work with this balancing act a healthy population of predators and parasites will become established. In fact going organic may even eliminate many pests. Sometimes the most important change needed is attitude.

Organic field days can be arranged by your field service. Details of how to produce organic tree fruits can be found in the Organic Tree Fruit Management Guide available from the Certified Organic Association of BC (Tel: 250 260-4429 email: [email protected]).

Visit Cyber-Help for Organic Farmers for information on organic tree fruit production and certification. Additional organic tree fruit production information can be found on the Canadian Organic Grower website.